Laboratory of bio and circular economy

Savonia University of Applied Sciences’ laboratory of bio and circular economy boosts companies' research and development work and promotes the utilization of industrial side streams as raw materials for recycled fertilizers and soil conditioners. In the start-up phase, the laboratory will focus on microbial-based biorefining and the development of recycled fertilizers and soil conditioners through cultivation experiments. The laboratory especially serves the local business life.

Biolaboratory is located in Sytytin building, in Savilahti, Kuopio.

BIOGAS AND BIOPROCESS RESEARCH

Biogas batch tests with BioProcessControl equipment

The methane production potential of the studied material or material mixture can be determined with the biogas batch test. A biogas batch test refers to a test in which no new input is added during the test, but the test is carried out with one "input" until the end.

The BPC equipment has 18 reactors with a capacity of 1 liter equipped with mechanical stirrers. The reactors are placed in a water bath, so the experiments can be carried out either in a mesophilic (35-38 °C) or thermophilic temperature range (55 °C). The accumulation of biogas and the proportion of methane are measured cumulatively from the reactors.

The tests are started using bacterial transfer from an already operational biogas plant, the share of the effect of which is reduced in the calculation of the results. Biogas batch tests are done in accordance with method VDI 4630 (2016).

The hydrogen production potential can also be determined with the equipment in the same way.

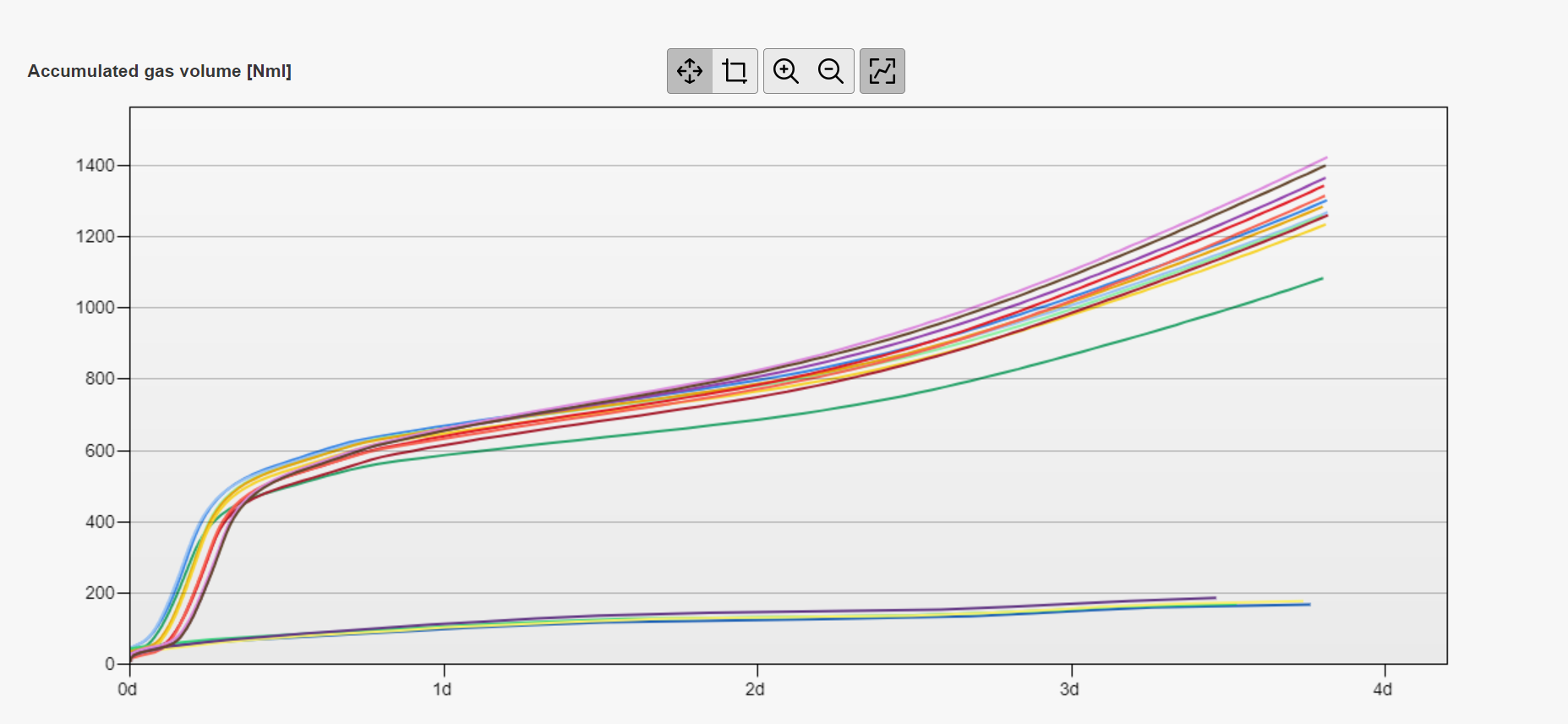

The BioProcessControl equipment stores the data in the database as the total gas flow (Accumulated gas volume Nml) as a function of time.

The gas flow is recorded by the equipment in every minute, so the data can be viewed on a minute, hour and day level. In addition to the total flow rate, the data is stored as the amount of methane in the same unit.

Data from the software can be downloaded as an excel file and can be easily processed further.

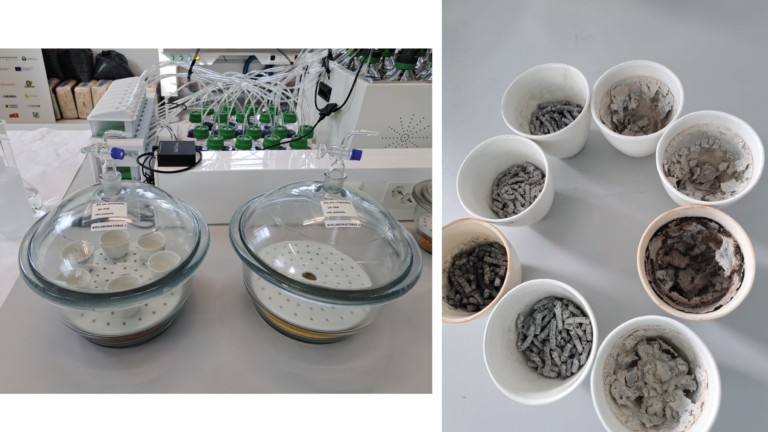

Biogas batch tests with 5l capacity reactors

The methane production potential of the studied material or material mixture can be determined with the biogas batch test. A biogas batch test refers to a test in which no new input is added during the test, but the test is carried out with one "input" until the end.

As second option, the tests in the biolaboratory can be carried out with 5l capacity reactors, where the gas is collected in a separate gas collection bag and analyzed using the volume measuring tank in the picture and the Biogas5000 gas analyzer. The analyzer detects methane, carbon dioxide and oxygen in volume percentages and hydrogen sulfide at the ppm level in the gas mixture.

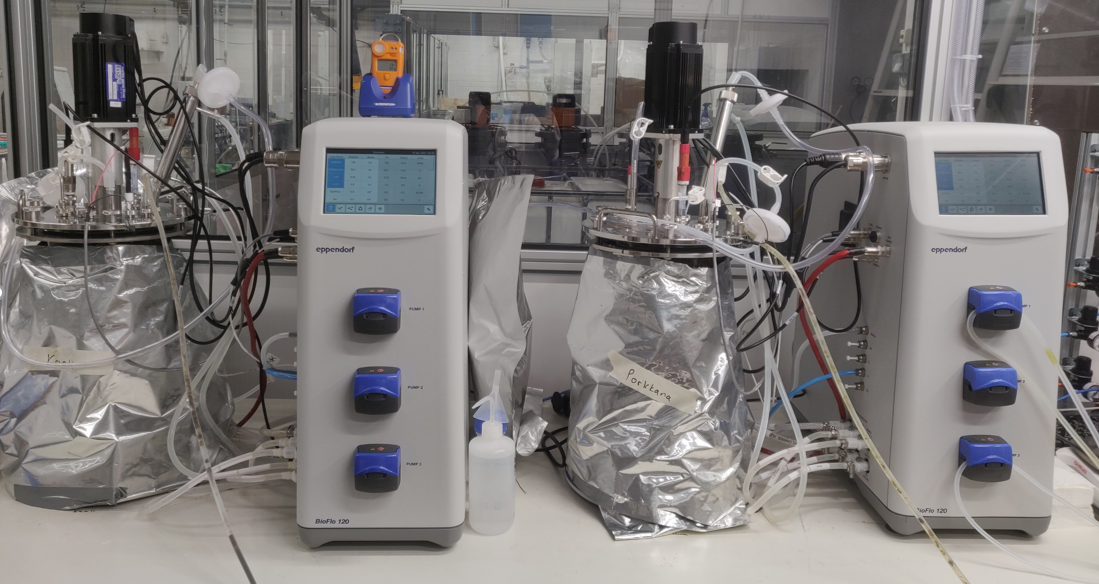

Fermentation equipment

The bio and circular economy laboratory has two fully automated fermentors for microbiological research that can be operated batch or continuous. Conditions can be adjusted to be oxygenated or deoxygenated as needed. The fermentors can be processed in series or in parallel and the reactors have a volume of 5l. The equipment includes mechanical mixing and temperature control from 5 degrees to 70 degrees (water jacket & heating plate). The control unit has integrated 3 separate pumps, which enable e.g. nutrient supply and automatic pH adjustment. The equipment has on-line measurement sensors for pH, ORP and O2 and data storage in a database. Option for gas collection and collection and analysis of liquid end products.

BIOGAS 5000

The BIOGAS 5000 gas meter measures methane (CH4), carbon dioxide (CO2), oxygen (O2) and other gases in volume percentages. Gas meter gives hydrogen sulfide (H2S) as ppm. For reliable biogas analysis, there must be at least 0.5 l of gas. The equipment is intended for field use, so it can be used to perform measurements from other places as well, for example at a landfill.

GA-21 PLUS hydrogen analyzer

GA-21 PLUS hydrogen analyzer measures hydrogen and carbon dioxide in volume percentages (0-100%). For a reliable hydrogen measurement, there must be at least half a liter of gas.

Analyzes and methods offered for plants, soil samples, biomass, industrial side streams, fertilizers and bioprocess rejects

Determination of dry matter and organic matter

Determination of dry matter and organic matter

An essential part of biogas studies is to find out the amount of dry matter and organic matter in the feed before and after the tests. The determinations are made in the laboratory based on the standard SFS3008 determination of water, sludge and sediment dry matter and annealing residue. Based on the determination, it is possible to evaluate how well the feed is suitable for the biogas process, and based on the TS/VS reductions, it is possible to evaluate how well the material breaks down in the process. Determinations are made in crucibles brought to standard weight and cooling is done in desiccators.

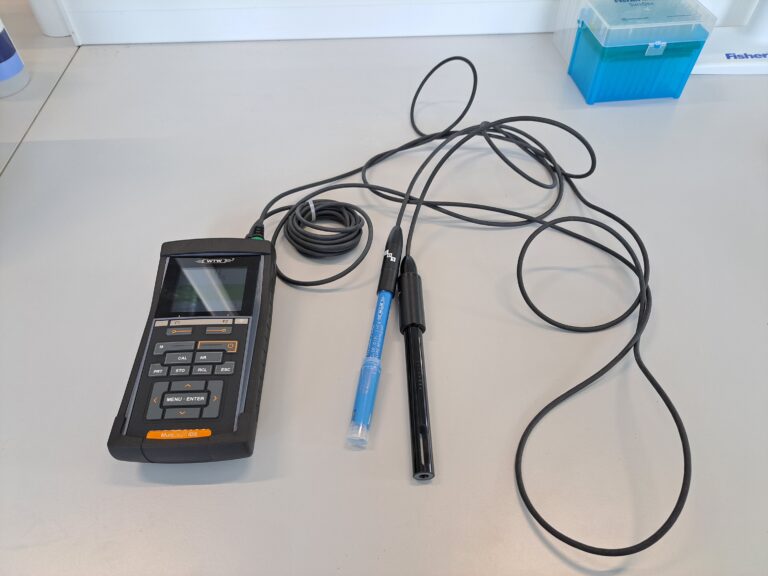

WTW Multi 3620 IDS multimeter

The operation of microbiological applications also needs accurate monitoring analytics. The most typical parameters to monitor are pH, conductivity, oxygen and reduction potential. The exact analysis of these is carried out in the biolaboratory with WTW's portable multimeter, which is suitable for both field and laboratory work.

Level shaker

Edmund Bühler's SM 30 C Control level shaker can be used to pre-treat laboratory samples. The level shaker also enables pH determinations in accordance with the standard SFS-EN 13037 "Soil conditioners and growing platform determination of pH value" and electrical conductivity determinations in accordance with the SFS-EN 13038 "Soil conditioners and growing platform determination of electrical conductivity" standard. Determinations according to the standard are used e.g. soil conditioner and recycled fertilizer in research work and in the determination of the pH of feed materials for biogas tests.

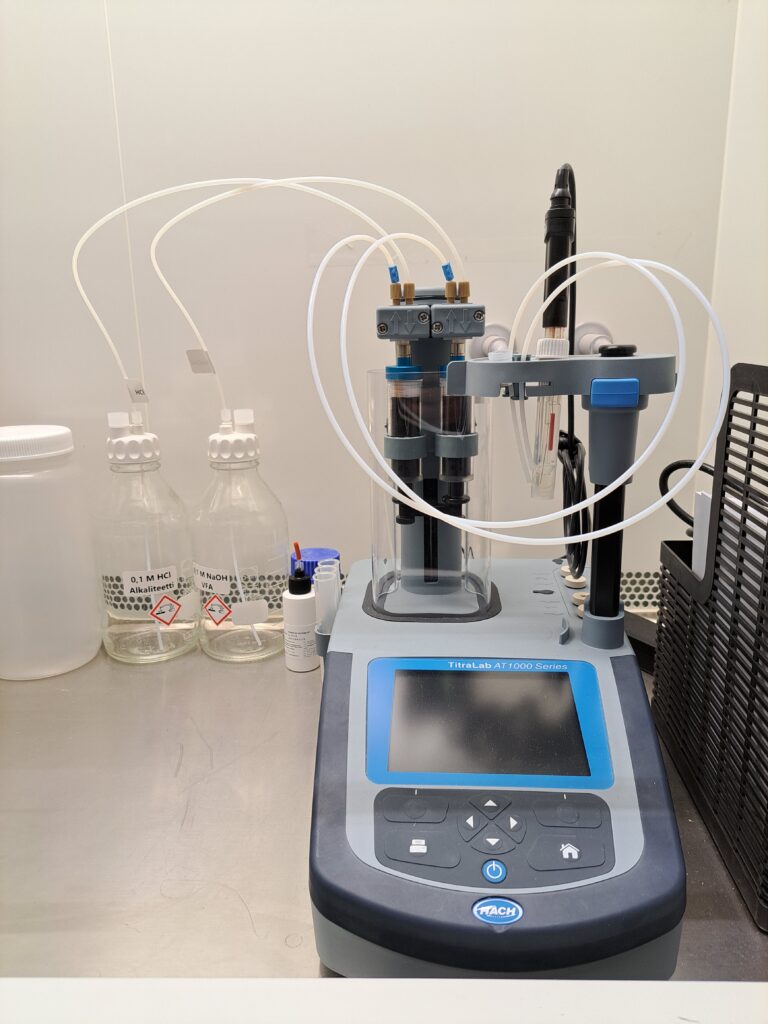

Automatic titrator for determining fatty acids and alkalinity

The operation of microbiological applications needs accurate monitoring analytics. The most typical parameters that are monitored in the production of both biohydrogen and biogas are the fatty acids and alkalinity formed in the metabolism of microbes.

Alkalinity describes the ability of the process to resist a change in pH and is caused by hydroxides, carbonates and hydrogen carbonates, as well as silicates, phosphates, borates, arsenates and aluminates. Alkalinity describes the buffer capacity of the reactor/process and is expressed as mg CaCO3/l or mmol/l. In a biogas plant, the recommended level is between 3500–5000 mg CaCO3/l.

By determining the concentration of volatile fatty acids, i.e. VFA (Volatile Fatty Acids), the functionality of the bioprocess can be verified. The determination is based on boiling the sample in acid so that (Bi) carbonates break down and carbon dioxide is removed. A functioning bioprocess depends on the balance between the bacteria present in it. If this balance is disturbed, the concentration of volatile fatty acids produced by acid-forming bacteria rises, dropping the pH to a dangerously low level. The determination of VFA can therefore determine the optimal level of fatty acids and guide the microbiological process in the right direction.

Heating cabinets and annealing furnace

The laboratory uses four heating cabinets/incubators and one annealing furnace. These enable controlled temperature conditions and can be used in the laboratory for sample drying, sterilization and other pretreatment. In the laboratory, the most typical applications of heating cabinets are biogas input experiments and drying of plant samples from cultivation experiments before analysis.

Scales and weighing capacities

Mettler Toledo XS204

max 220 g (d = 0,1 mg), weighing with 4 decimals

Analytical scale

Mettler Toledo XSR205DU

max 220 g (d = 0,01 mg / 0,1 mg), weighing with 5 decimals

Analytical scale

Mettler Toledo MR6002

max 6200 g (d = 0,01 g)

(Upper cup scale / precision scale)

Multi-element analysis

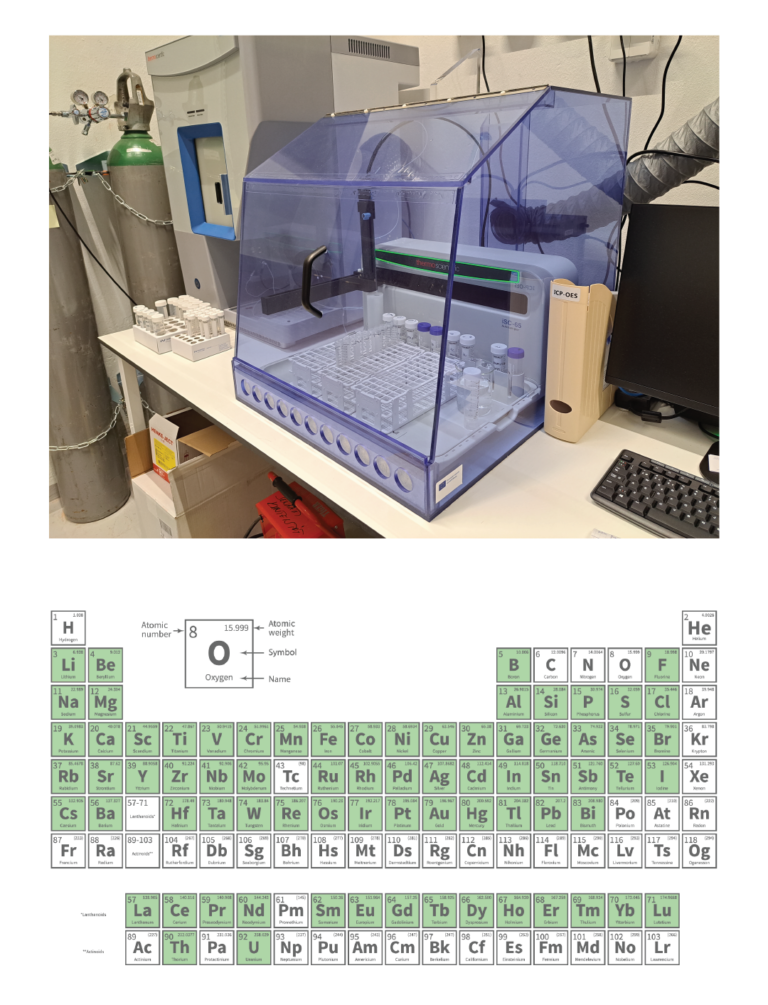

ICP-OES - Inductively Coupled Plasma Optical Emission Spectroscopy

ICP-OES enables the determination of up to more than 70 elements. In ICP-OES technology, the measurement range is typically wide: the ratio of the concentrations of the lowest and the highest element measured at the same time can be 1:1,000 or even 1:10,000. Thus, the need for sample dilutions is minimal.

Samples can be measured as:

1. Qualitative measurement – qualitative measurement of the elements contained in an unknown sample.

2. Semi-Quantitative measurement - quantitative measurement - the device estimates the concentrations of elements with 10% certainty.

3. Quantitative measurement – accurate quantitative determination of elemental concentrations. Unknown samples are compared to known measured samples

For ICP-OES analysis, the samples must be treated as liquid form, which can be done with a microwave acid digestion.

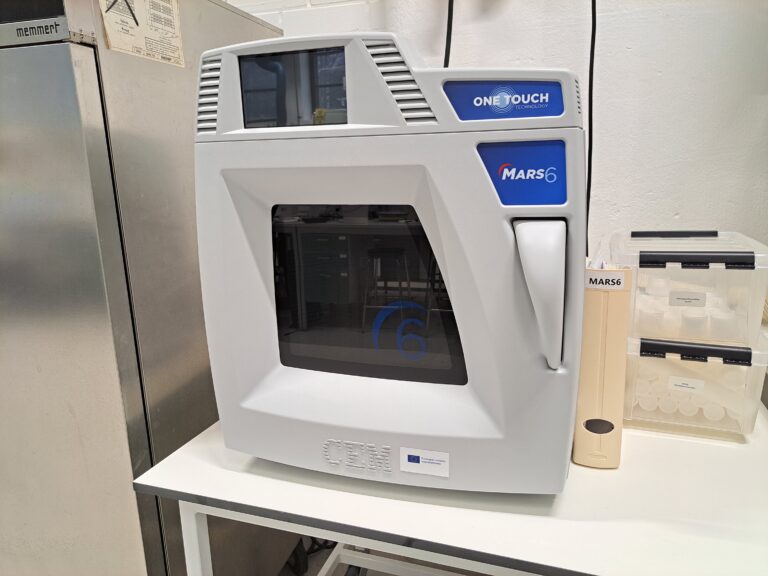

Microwave Acid Digestion

Decomposing solid samples into liquid form is done by dissolving the sample to be analyzed with a suitable solvent. The solvent is chosen so that the sample decomposes almost completely, the non-degraded parts can be filtered out of the sample.

In microwave acid digestion, the sample is exposed to a strong acid solution in a closed container. The temperature and pressure of the container is increased by using microwaves. The high pressure prevents the sample from boiling and contamination. The increase in temperature and pressure accelerates thermal decomposition and the dissolution of heavy metals.

In the biolaboratory, the samples are decomposed either with nitric acid or aqua regia in a 24-place sample container. Typically, the amount of sample required for acid digestion is 5 g.

Elementar vario MAX cube

Elementar's vario MAX cube analyzer can analyze total nitrogen (TN) and total carbon (TC) as well as organic carbon (TOC) and inorganic carbon (TIC) using a different program.

Elementar has several methods for different sample matrices. The method is chosen according to the moisture or organic matter contained in the matrix. Solid samples can be analyzed with the device. Samples do not need to be dried before analysis, so the device is also suitable for the analysis of samples containing moisture.

The device has a 90 crucible autosampler. The samples are analyzed in a steel crucible and in an incinerator. The incinerator consists of three vertical columns: combustion, post-combustion and reduction column. Post-combustion is needed to ensure complete combustion of the sample. The device has automatic ash and water removal. Helium is used as carrier gas.

SOIL CONDITIONERS AND RECYCLED FERTILIZERS

Arch greenhouse (18 m2)

The greenhouse enables research and development of recycled fertilizers and soil conditioners based on underutilized side streams. The greenhouse can hold approximately 100-150 submersible pots (Ø 25 cm) with a soil capacity of 6 liters and a water storage capacity of 2 liters at a time. The order of the pots can be randomized and typically the test matrices are repeated in 3-4 parallel pots. Testing different growth ground is also possible. The experimental layout of cultivation experiments can be implemented to correspond to the amounts of sowing, fertilizer and liming used in agriculture by relating these to the pot scale.

EQUIPMENT MAINTENANCE

DEKO 260 washing and disinfecting machine

High-quality equipment maintenance in the bio and circular economy laboratory is provided by the DEKO 260 washing and disinfecting machine, which meets the requirements of standards EN ISO 15883-1 and EN ISO 15883-2. The washing machine enables efficient and fast washing and disinfection programs for the needs of the laboratory, while offering a high overall washing capacity. The washing machine is suitable for various laboratory containers, from a 10 liter plastic bucket to a 20 ml measuring bottle.

Merck's Elix Essential and Synergy water purification systems

Merck's Elix Essential water purification system and a 60-liter tank for ion-exchanged water. Elix Essential produces ion-exchanged water (15 l/h), i.e. pure water (type 2) for laboratory needs. Ion-exchanged water is used e.g. in general laboratory applications, such as rinsing electrodes, diluting samples, preparing solutions, and as input for ultrapure water (type 1) water purification system (Synergy).

Ion-exchanged water is stored in a 60-liter polyethylene tank, which is designed to minimize possible contamination risks during water storage. It is also possible to lead ion-exchanged water from the water tank to the laboratory's washing machine for final rinsing of dishes.

The Merck Synergy water purification system produces ultrapure water (1.5 l/min) for laboratory needs. High-quality ultrapure water (type 1) is used in the most critical applications and advanced analytical methods, such as ICP-OES equipment.